Providing a decisively clearer view of real deformation at Bingham Canyon

OVERVIEW

The Kennecott Copper Mine (Bingham Canyon) is 25 miles southwest of Salt Lake City, Utah, USA. The mine, in production since 1903, is one of the world’s largest and deepest open-pit mines and employs over 2000 people. Owned by the Rio Tinto Group, it has produced more copper than any other mine in history. In 2020, the Kennecott operation became the first in the world to be awarded the Copper Mark, the industry’s first and only independent assurance programme – verifying the copper is responsibly produced.

CHALLENGE

In complex atmospheres, especially at large mines, atmospheric variability can hinder the ability of ground-based radars to detect movement, especially at its early stages. Due to the extensive width of the pit and climatic challenges at Kennecott Mine, rapid atmospheric changes are common.

Image 1: An image of the extensive pit taken by the radar.

SOLUTION

GroundProbe delivered an SSR-Omni equipped with Precision Atmospherics® to Kennecott Mine to demonstrate its capability in the site’s rapidly changing atmospheric environment.

Precision Atmospherics® is a revolutionary atmospheric correction algorithm. It resolves ambiguities in the deformation data from the noise caused by the most turbulent atmospheric conditions. The resultant reduction of atmospheric noise produces smoother plots for easier navigation of data sets and clean maps that immediately show areas of interest, essential in identifying real movements.

In May, in the lead-up to and during a snowstorm, a rapid build-up of atmospheric changes caused clutter in the data, making it difficult for the geotechnical team to distinguish real deformation from that caused by the atmosphere.

Precision Atmospherics® was used side-by-side with GroundProbe’s long-standing atmospheric correction algorithm, Stable Reference Areas (SRA), thus providing a point of comparison in real-time.

RESULTS

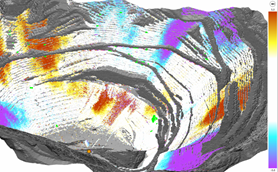

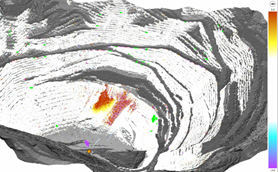

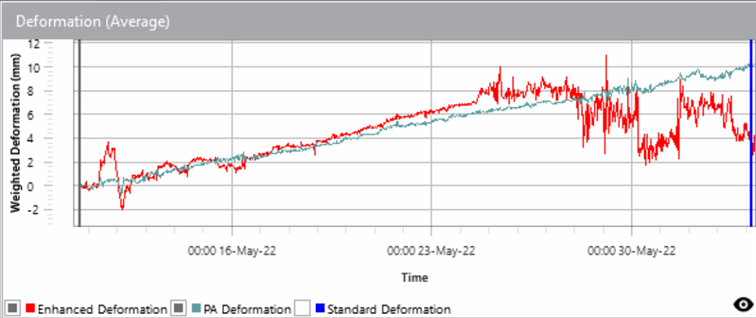

The results for the geotechnical team at Kennecott Mine were clear. The radar images show how Precision Atmospherics® cleaned the atmosphere from the rapid changes leading up to the snow fall period (image 2). The deformation vs time plot shows how Precision Atmospherics® reduces the noise in the plots, making it easier to identify deformation trends. Image 3 shows the deformation plot on an area that was stable, and Image 4 a sub-bench scale instability, both processed with SRAs and Precision Atmospherics®.

Image 2: The same radar data set before the snowstorm, on the left, processed with SRA, and on the right, processed using Precision Atmospherics®. In the short time window, only movement on loose materials was detected, and this is shown in red on the map at the right.

Image 3: Deformation vs time plot on a stable slope area. Red: Data processed with SRAs. Green: Data processed with Precision Atmospherics®.

Image 4: Deformation vs time plot of a sub-bench scale instability. Red: Data processed with SRAs. Green: Data processed with Precision Atmospherics®.

“The Precision Atmospherics® algorithm effectively managed a variety of atmospheric conditions, including blast and wind-induced dust plumes, rain, and snow, which resulted in significantly less contaminated data,” said Dustin Hicks, one of Rio Tinto’s Senior Geotechnical Engineers.

Because noise is reduced, Precision Atmospherics® enables tighter alarm thresholds to be configured. This means fewer false alarms and the ability to alarm for smaller movements earlier and with more certainty.

“It reduces the noise on a scan-by-scan basis, which opens the door for tighter alarm configurations that would otherwise overburden the geotechnical team.”

The algorithm simultaneously measures and tracks rapid and slow trends on the same data set, and unlike other techniques, no post-processing is required for the detection of slow movements.

“One of the goals of Precision Atmospherics® for the team here at Kennecott Mine was to see things earlier than we typically would with other systems, without the need to sub-sample the data. With Precision Atmospherics, we have been able to track rapid deformations. However, we were able to focus on and detect very slow-moving areas that typically would require post-processing to track them. The information was presented in one unified data feed, making it easy for us to understand and work with during our busy daily routines.”

As with all of GroundProbe’s innovative, cutting-edge technologies, rigorous testing with valued partners is paramount. Precision Atmospherics® is no exception.

“Something that we appreciate in GroundProbe’s approach is that we, as users, have an input into the algorithm’s configuration. Precision Atmospherics can run multiple configurations at the same time and features the capability to reprocess a wall with better configurations. This is something that my team has been wanting to see, and it is great to see this feedback now implemented.”

Precision Atmospherics® is proving to be safety-critical tool for the geotechnical team Kennecott Mine.

Precision Atmospherics® is a step change in how we manage atmospherics at our site. We’re seeing superior results by several metrics, especially during inclement weather when reliable data is needed most.”