GML Monitors Rear Wall of Shaft to Determine Optimal Targeted Ground Support

TARGETED GROUND SUPPORT

OVERVIEW

Underground environments are dynamic by nature, with the effectiveness of ground support consistently changing. Through monitoring, areas of high risk can be identified and rehabilitated in a targeted way. At a large, well-known hard rock mine in Queensland, Australia, visual inspections on the rear wall of a shaft showed cracking in the shotcrete.

CHALLENGE

GroundProbe’s challenge was determining where the movement was occurring as onsite Geotechnical Engineers were uncertain if the entire shaft was moving, if the pillars were moving, or if the whole drive was on the move.

The potential for rock falls was a significant safety concern; however, shutting down the shaft for rehabilitation involved shutting down the entire mine – adversely affecting production levels.

SOLUTION

GroundProbe immediately recommended the installation of GML together with its Convergence Monitoring Module, due to its capability of detecting rock and ground support movement within submillimetre accuracy and unprecedented range of features and benefits – targeted explicitly at underground monitoring.

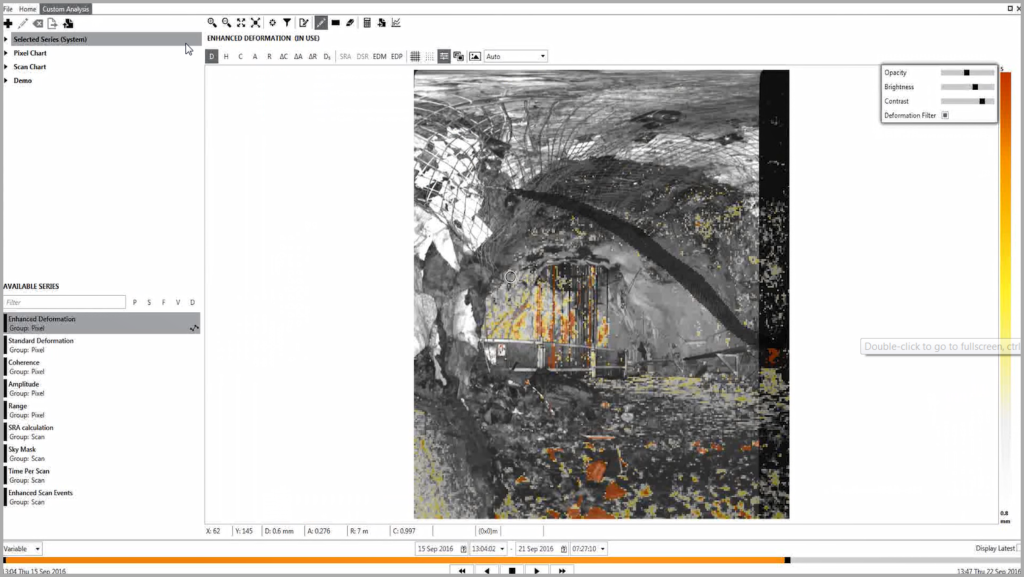

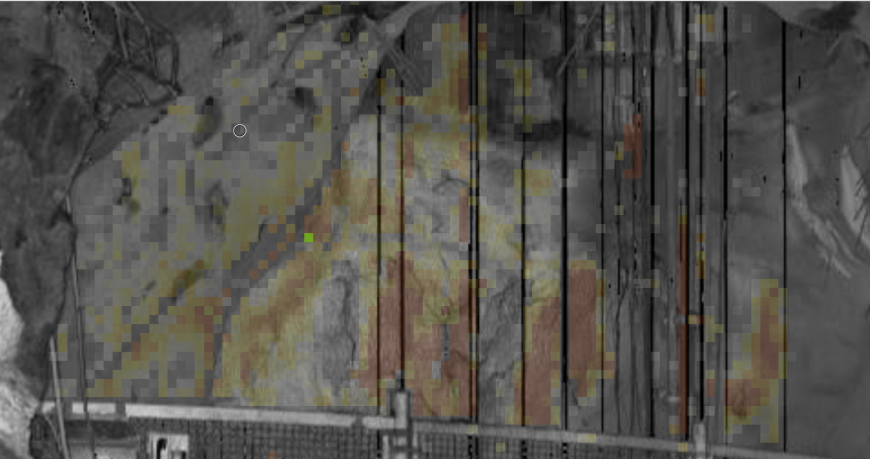

Complimenting the advanced hardware offering, GroundProbe’s intuitive visualisation software SSR-Viewer. The software enabled the geotechnical team to collect daily data, highlighting movement hotspots represented by a colour gradient heatmap draped over a photographic representation of the area.

RESULTS

The data gathered by the GML’s scans determined that convergence was indeed occurring, predominately around the cracked areas.

“The data showed linear to regressive movement occurring, particularly in the structurally controlled areas.”

– Peter Saunders, Head of Geotechnical, GroundProbe.

However, the data also proved that sections of the wall thought to be moving were, in fact, stable.

With this vital information in hand, the Geotechnical Engineers only needed to target the ground support rectification in the areas proven to be moving.

As a result, the shaft was only closed for a time, with GML monitoring continuing upon completion.

Said Mr Saunders,

“The results of the targeted ground support could be seen immediately. Identifying the mechanisms that drive convergence and the regions showing maximum displacement allows for targeted, efficient ground support installation. We can also use GML to monitor the effectiveness of that support post-installation.”

Mr Saunders further explained the benefits of the GML’s accuracy and precision in contrast to conventional measurement tools:

“Generally, we need to allow for anisotropy and never assume that convergence in a tunnel opening will be uniform. Using a point or line measurement tool, like convergence tape or prisms, may provide misleading information, as opposed to the full spatial resolution achieved with GML. This information can be used to make high-value decisions that can directly impact the profitability of a mining operation, so we need the decision confidence that GML provides.”

Mr Saunders concluded by discussing the practical applications of the GML to maximise safety and productivity concerning mine planning:

“We can now monitor the ground effectively with GML to better understand the regional impact of mining-induced stress, including the direct measurement of the impact and effectiveness of backfilling. We can then use this information to optimise short and long-term mine planning strategies, maximising asset value and minimising costs.”

Operationally insignificant, while the GML monitored the area, a small rockfall was detected in the drive near the shaft. The GML noted the movement 45 minutes before it fell. This shows the highly accurate and precise nature of the GML as a real-time, underground monitoring solution for convergence.

GroundProbe is proud to have shared its world-class expertise in providing real-time solutions for measuring and monitoring geohazards to restore ongoing onsite mine safety..

GroundProbe is the most trusted brand for real-time geohazard monitoring. With a track record that speaks for itself, our fleet of cutting-edge technologies deliver the most precise and valuable data.

|

|

| Image 1. GML data as seen via SSR-Viewer’s colour gradient heatmap. | Image 2. GML data as seen via SST-Viewer’s colour gradient heatmap |

AUSTRALIAN CONTACTPeter Saunders |

MEDIA CONTACTJustin Brosnan |